Aluminium Extrusion and Processing

We have solutions for aluminium extrusion plants, including extrusion software, heating technologies for extrusion containers, die ovens, tools, and special coated extrusion dies for the production of accurate, complex aluminium profiles.

In addition, we represent premium manufacturers of aluminium processing machinery, in Asian markets.

Atieuno is a highly specialized Aluminium Extrusion Software company, that develops vertical Industry 4.0. solutions leading the aluminium extrusion companies through their digital transformation and promoting higher performance in terms of productivity, quality, and sustainability. Their portfolio includes multiple modules solutions like:

- EMS Ecosystem 3rd generation – Extrusion Management System

- Extrusion Intelligence - advanced extrusion analytical tool

- Ulixes - a complete suite that check the aluminium profiles’ feasibility

- Theoria – the most advanced extrusion planner

- Press Supervisor - allows the fine-tuning of process parameters

- Nitrogen – liquid nitrogen for high quality extrusion

- Cast House –real-time process supervision in re-melting department

extrutec GmbH - a specialist and innovator for heat transfer technology to the metal extrusion industry, offering technological features that have benchmark character and are customer-specific answers to the respective conditions in extrusion plants.

The most common heating methods in the metal extrusion industry are gas-heated, inductive or convectional heated systems. Many of these systems are designed for use with specially developed extrutec heat recovery systems. The company is globally recognised for extremely energy efficient heaters with low consumption values, operated on a remarkable low maintenance level.

In-house expertise for engineering & production of a wide range of electrical equipment and control systems, assembly, installation & optimisation, worldwide spare parts availability and system support services make extrutec a reliable partner for all heating applications.

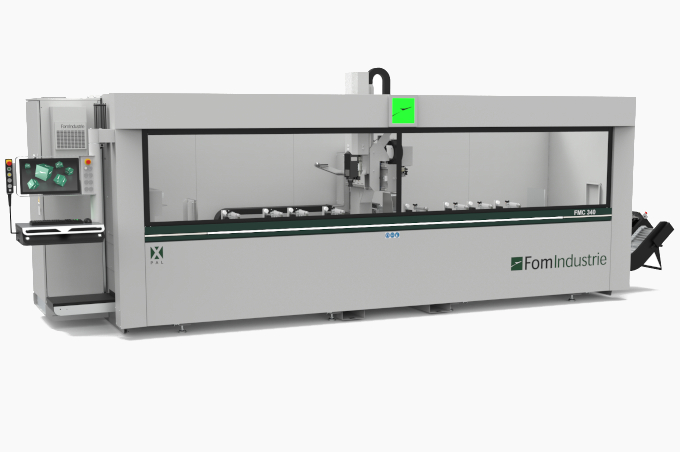

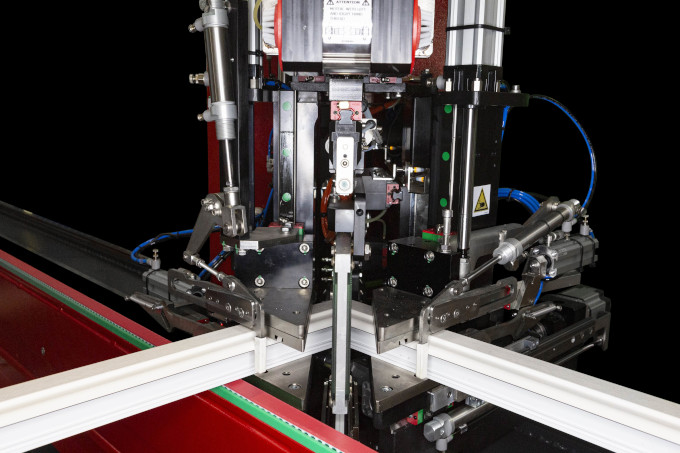

Fom Industries offers a wide range of high technology machine tools for cutting and machining aluminium extrusions. Fom Industries is part of the Fom Group, which provides solutions all along the supply chain, with a special focus on the window manufacturing industry.

In Korea we are helping set new standards for innovative window and door systems with Graf Synergy (part of the Fom Group), a leading manufacturer of highly innovative production solutions for PVC and aluminium windows.

Increasingly challenging product requirements, faster process flows, frequent changes of billet alloys and demands for longer tool life – these are marks of today’s aluminum extrusion industry. As a result, precision temperature regulation systems have become essential for containers on extrusion presses. In addition to the development of higher quality steels and the geometric design of containers, improved heating and cooling are necessary. Coordination of service providers is critical for production and quality, since these factors impact on the useful life of containers and press tools.

Since 1962, Marx has been providing optimal solutions for all extrusion technology requirements:

- Heating systems for containers (1 - 8 zones)

- High-power cartridges (1 - 3 zones)

- Quick connectors

- Multi-point thermocouples

- Air cooling regulations

- Pre-assembled ring-connectors

Wherever high demands for precision and speed are placed on cutting, punching and drilling machinery, Pressta Eisele can optimize your job. Window and facade manufacturers, furniture makers, aviation and automotive suppliers are among their worldwide customer-base.

Since 1972, WEFA has been an innovative partner for the production of extrusion dies used in the automotive and construction industries, and in electrical engineering. Types of Coated Extrusion Dies (CED®):

- Cartridge® dies (interchangeable CVD coated cartridge dies fitted into die-holder and backer)

- Solid dies (coated die plate with backer and feeder plate if required) and

porthole extrusion dies (plate and mandrel entirely coated) - Sandwich dies (one or more coated plates and mandrel inserts fitted into a robust die holder)