Plastic & Rubber Processing and Laboratory

Plastic and rubber processing technology and quality control has been one of our core competences for decades. Plastic waste has become one of the most pressing environmental challenges of our time – and we are fully engaged with this issue. Improvements require a fundamental change in thinking about how plastics are made, used, and discarded. Challenges are best overcome by facing them, turning them into new opportunities.

We work closely with leading European and Asian manufacturers, providing strong support both locally and from Europe through dedicated, experienced sales and service staff in our various markets.

PRECISION MEASURING INSTRUMENTS

aboni GmbH is specialized in providing highly precise measuring instruments for determining residual moisture in solids – in a water selective way. Serving customers in the plastic processing industry as well as machinery equipment manufacturers, aboni is active in the fields of injection molding, profile and hose extrusion, as well as film and fiber production.

Their residual moisture analyzer HydroTracer HT3 has an extensive moisture content testing and is ideal for usage in production, laboratories as well as on the go. It determines the moisture of granulates, powders or finished parts with high accuracy, which is crucial for an optimal production process. Customers believe in aboni worldwide which results in over 2000 applications.

Furthermore, aboni also has the equipment for research and development purposes at command. Thus, they are able to realize new projects, create their own prototypes as well as experimental setups in a short amount of time. Their measuring instrument are innovative and customer-oriented while contributing to an environment friendly production by optimizing energy consumption and reducing waste.

LAB & PILOT SOLUTIONs

COLLIN develops intelligent laboratory, pilot and production lines in modular system for plastic processing companies as well as for research institutes and for the Food Industry. Being in business for almost 50 years COLLIN solutions are used for the development and the production of plastic products, material analysis, test series up to pilot tests which allow a scale up to production scale.

As part of the COLLIN product lines Food Feed Line, Teach Line, Lab Line, Pilot Line, Medical Line and Polytest Line, COLLIN develops individual solutions – platen presses, roll mills, calenders, extruders, compounders, mono or coextrusion lines, pressure filter tests, rheometers or optical inspection systems. Material manufacturers, compounding companies, film manufacturers, companies in the medical, pharmaceutical and industrial sector, universities, laboratories and research institutes count on COLLIN.

COMPOUNDING AND PROCESS ENGINEERING

ENTEX is the leading manufacturer of Planetary Roller Extruders and the leading supplier of solutions for complex process as well as product developments. They have over 160 intellectual property rights registrations to its name since its founding.

The ENTEX Planetary Roller Extruder covers the full scope of compounding and process technology for a wide range of industrial applications, including the plastics, rubber, chemicals, paint, recycling and food industries.

The ENTEX Planetary Roller Extruder is tailored to the individual production process and, due to its modular concept, offers a wide range of possibilities for compounding – even when dealing with complex reactive, cooling, degassing and mixing processes. The ENTEX Planetary Roller Extruder is able to use primary energy – making it both economical and sustainable.

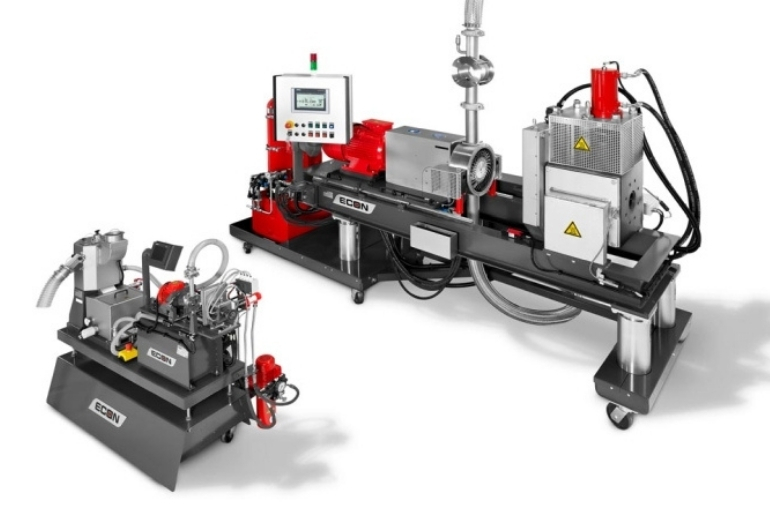

UNDERWATER PELLETIZING TECHNOLOGY

The Austrian company ECON has been a premier underwater pelletizing specialist for over 20 years.

Besides underwater palletizing, their product portfolio also consists of a vibration drying system as an alternative to the standard centrifugal dryer, an air pelletizer for processing wood and natural fiber compound as well as a pyrolysis furnace for environmentally friendly and gentle cleaning of extrusion and filter parts.

ECON offers tailor-made as well as energy-efficient solutions for their customers’ product lines. With their palletizers, they guarantee an easy and safe operation, and through continuous improvement they ensure constant development and innovation of their products.

Plastic Extrusion and Compounding in production scale

The core competence of our business partner Feddem is the development, design and construction of extrusion and compounding lines for the production of high-quality plastic compounds and masterbatches used in plastic goods manufacturing, the chemical industry, and mechanical engineering.

Fibre Extrusion Technology

FET designs, develops and manufactures extrusion equipment for a wide range of high value textile material applications in the global marketplace. The company has inhouse yarn and fibre engineering knowhow for designing extrusion equipment, which will allow their customers to consistently produce fibres of the highest quality. Typical applications for extruded yarn innovation:

- Biomedical materials, such as resorbable polymers for use in medical devices

- Specialized novel fibres from exotic and difficult-to-process polymers

- Sustainable polymers, biodegradable and composting materials

- Melt-spun fibres and yarns and textiles for a wide range of composites

- Functional textile materials, provided by polymer formulation or additives

FET has also considerable experience in the development of specialist sustainable polymers that have either eco-friendly end-of-life cycle or have been sourced from renewable resources.

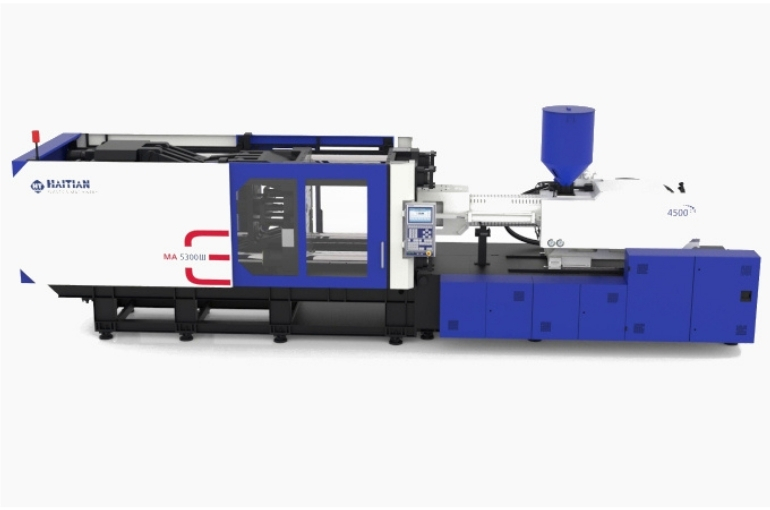

Haitian InternationaL

In terms of unit sales to global plastics processing industries, Haitian International is one of the world’s largest manufacturers of injection molding machines. Melchers Techexport is their exclusive partner in Sri Lanka, serving the local market with latest innovations and extensive services at a professional level. Haitian is continuously working on upgrades and new technologies, for an even brighter future.

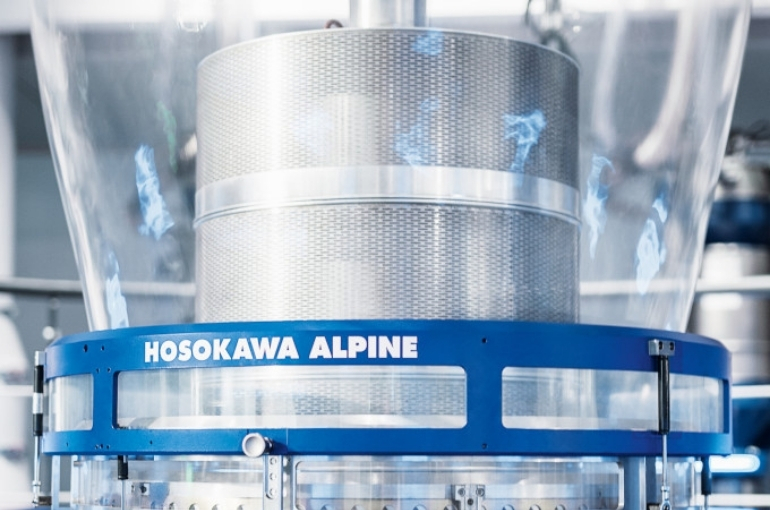

Blown Film Technology

Hosokawa Alpine ranks high among international suppliers of blown film lines and includes in its product portfolio blown film co-extrusion lines with up to 11 layers, mono-axial film orientation lines (MDO) and patented systems such as TRIO (Trim Reduction for Inline Orientation) for increased profitability. A global player, always a step ahead.